Choosing the Right Metal Casting Sealant for Strength, Durability, and Finish

When it comes to high-performance metal parts, choosing the right metal casting sealant can mean the difference between a component that lasts for years and one that fails far too soon. Whether you are working in automotive, aerospace, heavy industrial machinery, or any field that demands precision, selecting a sealant means balancing strength, durability, and finish. This article explores what to consider, why those criteria matter, and how to make a smart decision so your casting jobs deliver excellence every time.

Understanding Sealant: Purpose and Performance

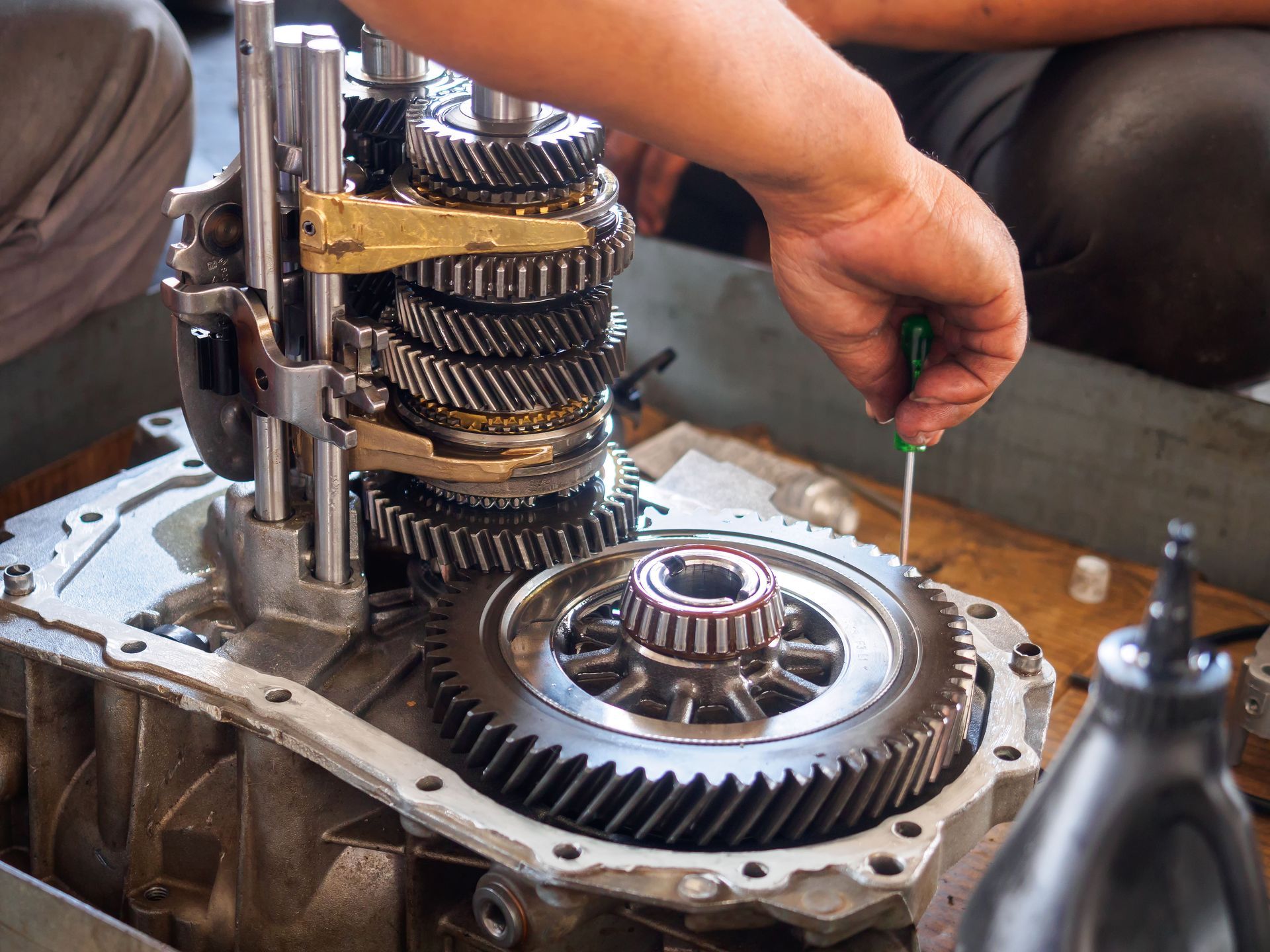

Every metal casting experiences some degree of porosity, microscopic voids, or imperfections that can permit fluid, gas, or contaminants to pass through. A well-formulated metal casting sealant fills those pores, creating barrier layers that improve strength, prevent leaks, and preserve the component's structural integrity. But not all sealants are alike. Their chemistry, curing characteristics, compatibility with the base metal, and resistance to environmental stressors all affect performance.

Strength is critical because cast metal parts often endure mechanical loads, thermal cycling, vibration, and pressure. A metal casting sealant must bond well, not crack, shrink, or degrade under these conditions. Durability comes into play when the sealant must resist corrosion, chemical attack, or fatigue over long operating lifetimes. Lastly, finish matters: even if a part is strong and durable, poor visual or surface finish can lead to trouble in downstream processes, sealing interfaces, or simply in customer satisfaction.

Evaluating Strength: Bond, Stress, and Compatibility

To ensure high strength in metal castings with sealant, you must first ensure compatibility between the sealant and the metal substrate. Ferrous metals (like iron or steel) behave differently than non-ferrous alloys (like aluminum, copper, or magnesium). The thermal expansion, conductivity, and surface chemistry differ dramatically. A sealant that works well on aluminum might fracture or delaminate when applied to steel under heat cycling, for example.

Next, assess the bonding mechanism. Do the sealant and metal need to be preheated? Is there a priming step? Does the sealant penetrate deeply into porosity, or is it just surface sealing? Deep impregnation often yields better strength under pressure, especially for parts subject to internal pressure or hydraulic loads. The curing process is also essential - whether it sets via heat, chemical catalysts, or ambient moisture - because improper curing can lead to weak bonds or residual stresses that undermine strength.

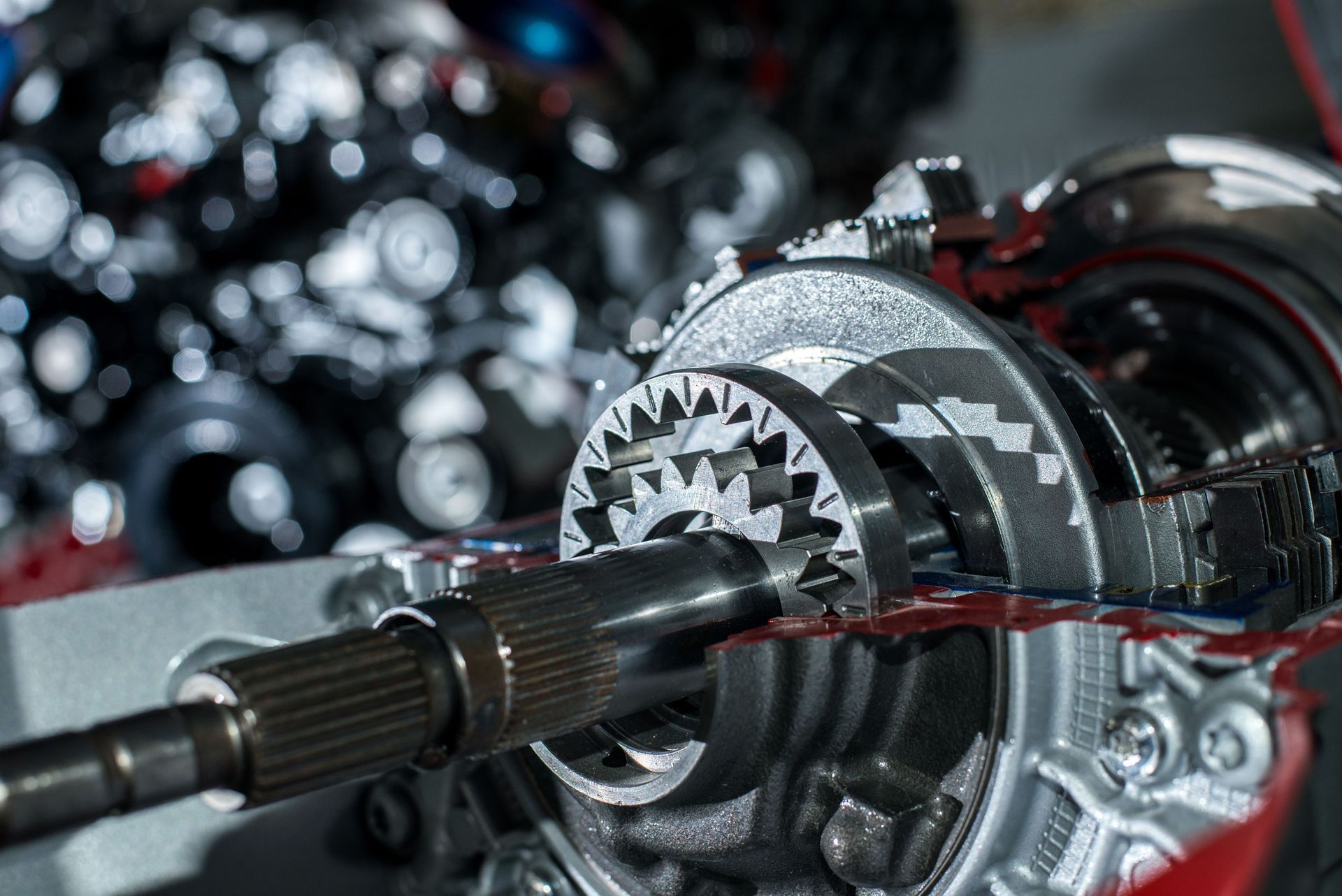

Finally, check performance under operational stresses: how it handles load, shear, impact, vibration. In many applications, parts are exposed to wide temperature swings, so a metal casting sealant must maintain adhesion and integrity without becoming brittle or losing flexibility.

Ensuring Durability: Corrosion Resistance, Chemical Stability, and Longevity

Durability is equally important. A metal casting sealant helps prevent corrosion by sealing pathways where moisture and salts or chemicals could otherwise attack the metal internally. If the sealant itself degrades, discolors, or cracks, it loses its protective function and may even accelerate failure by trapping contaminants.

Chemical stability matters. Depending on the application, a casting may be exposed to fuels, oils, coolants, acids, or alkaline substances. The sealant must resist chemical attack, swelling, degradation, or embrittlement. Heat is also a durability factor: at elevated temperatures, some sealants break down, lose adhesion, or degrade their molecular structure. A durable sealant keeps its properties over the full expected temperature and chemical range.

In addition, consider mechanical durability over time: repeated stress, vibration, and thermal cycling can fatigue both the metal and the sealant. A durable metal casting sealant resists cracking under those conditions, resists delamination, and retains bond strength over many cycles rather than degrading rapidly.

Optimizing Finish: Surface Texture, Aesthetics, and Secondary Processes

A metal casting sealant's finish influences both function and appearance. Surface texture must be smooth or uniform enough not to interfere with gaskets, coatings, machining, painting, or polishing. If the sealant leaves a rough or uneven texture, it may introduce stress concentrators, leak paths, or interfere with tolerances. A sealant should not shrink or pull away from edges, leaving ridges or gaps.

Aesthetic finish can matter in visible parts, or in applications where uniformity or branding is important. Even in industrial settings, a clean and consistent finish signals quality, helps with heat transfer, reduces places where dirt or contaminants gather, and eases maintenance.

Secondary processes must be considered. Will the sealed casting be machined, plated, painted, or welded after sealing? Some sealants are compatible, others can interfere or damage tooling. A sealant that resists high-speed abrasion if machining, or that endures the stresses of welding (without out-gassing, warping, or blowing off) can help avoid costly rework or rejection.

Balancing Strength, Durability, and Finish: What to Look For

To balance these three criteria-strength, durability, and finish-you'll need to evaluate a few key factors together rather than in isolation. First, material compatibility: choose a metal casting sealant formulated for the particular alloy you're casting. Next, porosity sealing method: impregnation vs surface sealer. Impregnation produces better depth of fill, helping both strength and durability.

You should also examine curing method: fast cure does not always mean best finish; high heat cure may improve bond but may risk distortion or affecting surface finish. Choose a cure process that your factory environment can handle and that fits with your production schedule.

Think of environmental exposure: if the part will be outdoors or submerged, prioritize durability. If the part will be seen or touched, or will receive coatings, prioritize finish without sacrificing strength. What about cost trade-offs? A higher-performance metal casting sealant may cost more per unit, but savings from reduced failures, fewer repairs, lower reject rates, and higher customer satisfaction can more than pay back over time.

Considering Industry Trends: Growth, Regulation, and Quality Standards

Awareness of industry trends helps guide your choice. The metal casting industry is growing fast. According to The Insight Partners, the metal casting industry is projected to reach $253,220 million by 2030. This growth means increasing demand for reliability, stricter quality standards, and more competition among sealant providers. Regulatory standards for emissions, toxicity, outgassing, environmental impact, and worker safety also tighten year after year. As a result, you need a metal casting sealant that is compliant with applicable environmental safety rules, non-toxic, low VOC or odor, and doesn't off-gas under operational or curing conditions.

Customers and OEMs are also more demanding about consistency and documentation: traceability, testing, certifications. Sealants that can be tested, whose performance data is published, and that are backed by the supplier are worth considering because they reduce risk. Also, shipping and servicing matters: if a sealant fails, how easy is it to get replacement or resealing? A provider with experience, spare parts, or technical support will help ensure long-term success.

Choosing the Right Product: What You Should Compare

When you narrow down your options, compare product data sheets side by side. Look at tensile and shear adhesion to various substrates, compatibility with your metals, maximum temperature, chemical resistance, shrinkage rate, curing time, safety data sheets. Ask yourself: will the finished product meet both mechanical requirements and aesthetic requirements? Will it survive long term in the environment it will face?

Find out about sample testing from suppliers. Seal small batches using candidate metal casting sealants, subject them to thermal cycling, pressure, chemical exposure, and see how finish holds up. Test scaling: sometimes performance looks great on small cast parts but falls short when volume, size, or geometry change. Also check after treatment: would your sealant hold if the part is painted, welded, or machined post sealing? Compatibility here is crucial.

Selecting the Right Supply Partner: Support, Service, and Standards

Even the best metal casting sealant depends heavily on the supplier's expertise and service. Choose a supply partner who understands both your metal casting application and your finish needs. Make sure they are responsive, provide technical assistance, offer sample processing, and deliver consistent product quality.

Verify whether the supplier has quality management systems (ISO or equivalent), how they handle non-conformances, what their lifetime track record is. Consider safety: non-toxic, low odor or odor-free, no harmful off-gassing. Also look for ease of logistics: can they ship nationwide; can they provide fast delivery; can they handle quick orders or emergencies?

Leading providers often offer metal casting impregnation services alongside sealant products, ensuring integrated solutions, better support, and more consistent outcomes. That can make a difference in real-world operations, where sealant performance in the manufacturing line often dictates product quality downstream.

Final Decision: Matching Application to Sealant Traits

By the time you are choosing a specific product, you should map your requirements in three dimensions: the mechanical strength your part must support, the environmental and chemical durability it must survive, and the finish or surface requirements you need to meet. Compare potential metal casting sealant candidates in those dimensions.

If you are sealing pressure-bearing parts, prioritize strength and chemical/temperature durability, even at the expense of some cosmetic finish. If part appearance or surface finish is critical, you might accept trade-offs by refining preparation, curing method, and choosing a sealant rated for superior finish. If the component's environment is harsh (moisture, salt, heat, cycles), leaning toward durable chemistry and proven track record is essential. Don't forget cost-of-ownership: a higher initial expense for a very good metal casting sealant can yield savings in reduced downtime, fewer failures, less maintenance, and better customer satisfaction.

Choosing the right metal casting sealant is not just a matter of picking the highest spec or the lowest price-it's about alignment between your part's demands and the sealant's performance in strength, durability, and finish. With careful evaluation, testing, and the right supplier, you can ensure your metal castings stand strong, stay durable, and look professional for the duration of their service lives. If you're looking for metal casting sealant, contact A B Seals Inc today.

Share On: