The Role of Casting Sealers in Protecting and Enhancing Your Cast Creations

Casting sealers occupy a significant position in the world of craftsmanship and industrial production. They serve as a critical protective layer that enhances both the durability and aesthetic quality of cast creations. These sealers are applied to materials ranging from metal and concrete to plaster and resin, ensuring the integrity and longevity of finished products. Understanding the role of sealers allows creators and manufacturers to maximize the potential of their cast objects.

Definition and Purpose

Casting sealers are specialized coatings applied to the surface of cast materials to provide a superior finish and added protection. The purpose of these sealers is multifaceted; they not only shield the object from environmental and physical stresses, but also enhance its visual appeal. This is achieved by creating a thin, durable layer that resists moisture, chemicals, and wear, while also accentuating the natural luster and colors of the material beneath. Without such protective coatings, cast objects would be susceptible to a rapid decline in their physical and aesthetic properties. Applying a sealer is a vital step in many casting processes, ensuring that the item's functionality and beauty are preserved over time.

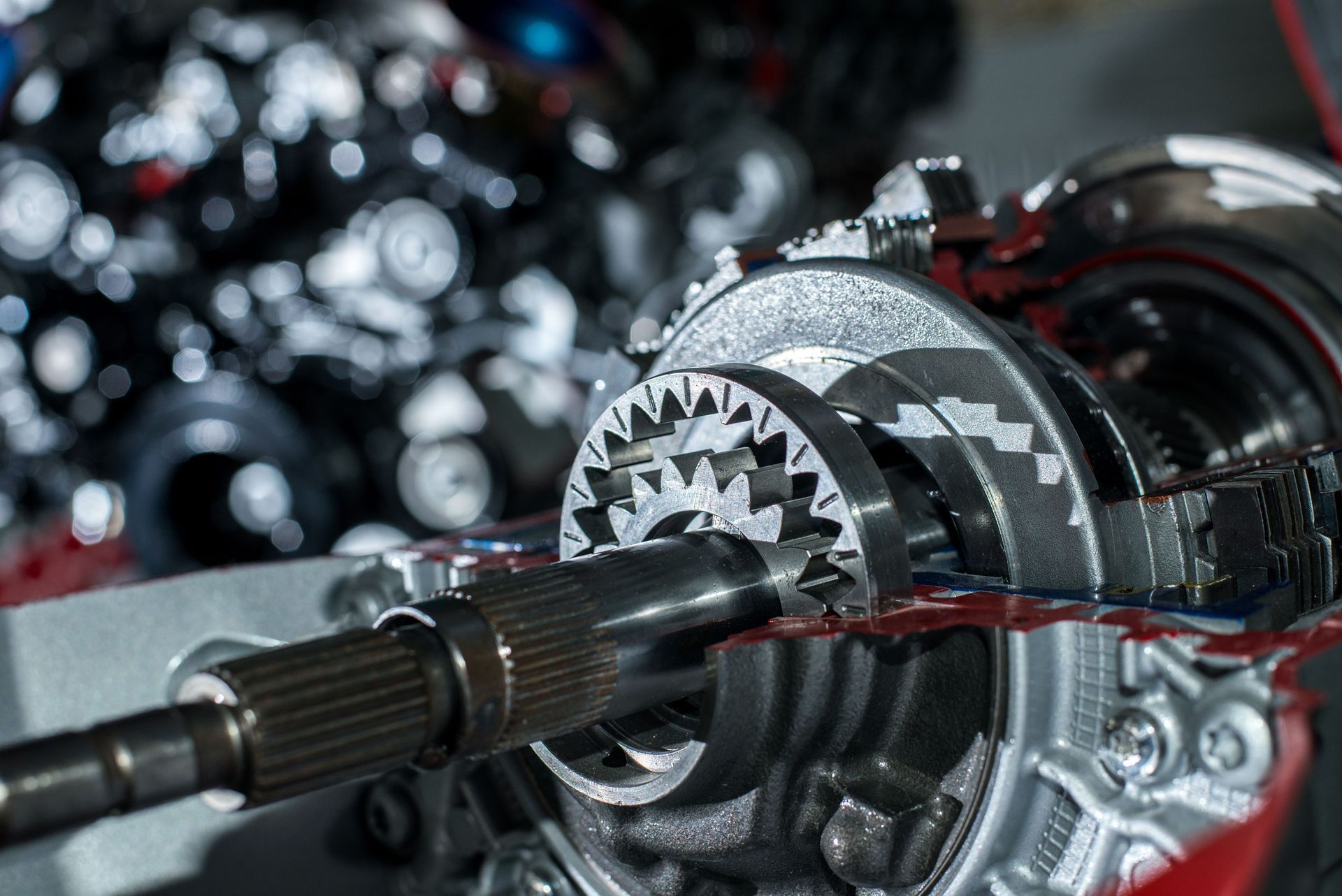

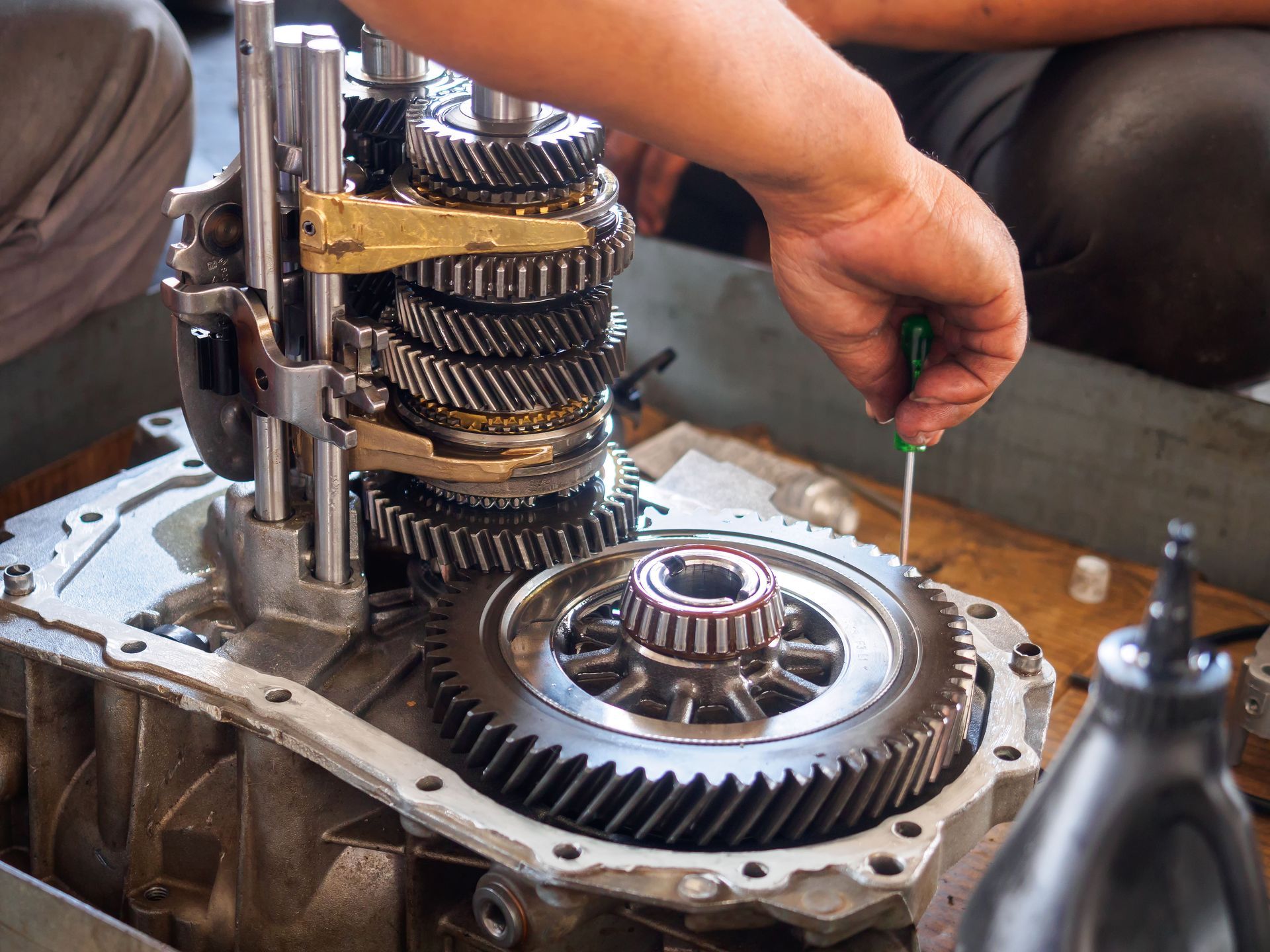

Types of Casting Materials

A diverse range of casting materials is available for various applications, including metals, concrete, plaster, resins, and ceramics. Each of these materials has unique properties and, therefore, demands specific types of sealers to maximize protection and enhancement. For instance, metal castings benefit significantly from sealers that provide exceptional corrosion resistance and inhibit oxidation. On the other hand, concrete and plaster need sealers that prevent moisture penetration and increase surface hardness. Understanding the specific requirements of each casting material is imperative to selecting the appropriate sealer that best suits the material's characteristics.

Varieties of Sealers Available

The market offers a wide array of casting sealers, each designed to cater to different materials and desired effects. Water-based sealers are popular for their environmentally friendly composition and ease of use, suitable for both indoor and outdoor applications. Solvent-based sealers, although more robust, are recommended for heavy-duty uses, especially in industrial settings where increased durability is important. Epoxy sealers are favored for their hardness and clarity, often employed where a high-gloss finish is desired. The variety of sealers ensures that there is an option to meet virtually any specific need, from routine household tasks to complex industrial projects.

The Science Behind Sealers

The effectiveness of sealers lies in their chemical composition and how they interact with the surface materials. These sealers are engineered to form a strong bond with the substrate, creating a protective barrier that is resistant to environmental and physical degradation. The active ingredients in sealers, such as acrylics, epoxies, urethanes, and silicates, each provide unique properties that fortify and enhance the cast object. The application of the sealer results in a molecular reaction that not only hardens the surface, but also fills in any microscopic imperfections. The science behind sealers is a testament to the sophisticated intersection of chemistry and art, aimed at achieving both preservation and aesthetic enhancement.

Historical Context and Evolution

Casting sealers have a rich history that dates back to ancient times, when protective coatings were essential for both functional and decorative purposes. Early sealers consisted of natural oils and waxes, which provided a basic level of protection for crafted goods. Over the centuries, advancements in chemistry led to the development of synthetic sealers designed to address specific durability and appearance needs. Modern sealers now incorporate cutting-edge technology, offering unparalleled levels of protection and aesthetic refinement. The evolution of sealers reflects the ongoing demand for innovation in preserving and beautifying materials across various industries.

Weather Resistance

One of the most significant benefits of sealers is their ability to provide superior weather resistance. These sealers form a resilient barrier that protects against environmental elements such as rain, UV rays, and temperature fluctuations. By preventing moisture ingress, sealers inhibit the growth of mold and mildew, which can cause structural damage and aesthetic deterioration. In geographical regions with harsh weather conditions, sealing a cast product becomes even more crucial to ensure its longevity and strength. The ability to withstand adverse weather conditions ensures that cast creations remain in pristine condition over extended periods.

Impact Resistance

A casting sealer contributes significantly to the impact resistance of the sealed surface. They provide an additional layer that absorbs shock and distributes forces, thereby reducing the likelihood of cracks and other forms of mechanical damage. This is particularly important for outdoor installations and objects subject to frequent handling or transportation. The enhancement of a cast product's impact resistance not only lengthens its service life, but also maintains its structural integrity and aesthetic appeal. Furthermore, impact-resistant sealers are a worthwhile investment in settings where safety and durability are paramount.

Prevention of Wear and Tear

Regular wear and tear can dramatically affect the usability and appearance of cast objects, making their maintenance a top priority. Sealers offer an effective solution by creating a durable surface that reduces abrasion and physical degradation, even under persistent usage. This protective layer is particularly valuable in high-traffic areas or industrial environments where cast materials are subject to constant friction. By minimizing wear and tear, sealers help maintain the object's original form and function, ensuring longevity and reducing maintenance costs. The preservation of both aesthetics and functionality highlights the invaluable role of sealers in prolonging the life of cast products.

Resisting Chemical Damages

In many industrial and commercial settings, cast items are exposed to various chemicals that can lead to surface degradation and structural compromises. Casting sealers create a non-reactive barrier on the surface of the material, effectively deterring chemical interactions that could potentially cause damage. Whether utilized in corrosive environments like factories or in situations where cleaning agents are frequently applied, these sealers prevent chemical penetration and dissolution. By offering this level of protection, sealers safeguard investments in costly equipment and components. Chemical resistance is, therefore, a critical consideration when selecting a sealer, ensuring operational continuity and maintenance of quality.

Long-Term Durability

Sealers enhance the long-term durability of cast materials by creating robust surface protection that withstands the test of time. Their application minimizes external impacts, such as environmental and chemical stresses, which can otherwise accelerate wear and degradation. As a result, the lifespan of a sealed cast product is substantially extended, providing a favorable return on investment over the years. According to the American Foundry Society, the metal casting industry supports over 160,000 jobs in the U.S., exemplifying the significance of maintaining durable and reliable cast products. Ensuring long-term durability plays a vital role in both economic productivity and the sustainability of industrial practices. Durable work means less waste over time, highlighting the importance of this skilled craft.

Casting sealers are far more than just finishing touches—they are essential tools that uphold the integrity, performance, and beauty of cast materials across a range of industries and applications. Whether protecting against moisture, chemical exposure, physical impacts, or daily wear, sealers provide a durable defense that extends the life and enhances the appearance of every cast object. From ancient methods to modern technological advancements, the evolution of sealers reflects a continuous effort to perfect and preserve the craftsmanship behind every cast. Contact A B Seals Inc of Sullivan, IL when you need metal work!

Share On: