Casting Impregnation: A Critical Solution for Porosity in Metal Components

Porosity in metal components is a widespread issue that can compromise strength, durability, and reliability. As molten metals cool during the casting process, air pockets and voids can form, creating weak points that affect performance. Casting impregnation provides a reliable, professional solution to eliminate these defects and reinforce the integrity of metal parts. This process seals microscopic pores with specialized resins, restoring strength and preventing future damage. Manufacturers across industries rely on expert casting impregnation services to ensure quality, safety, and long-term durability in their products.

Causes and Nature of Porosity

Porosity in metal castings results from trapped gases, shrinkage during cooling, or poor material flow within molds. These pores, though often invisible to the naked eye, can severely affect the structural stability of components. Shrinkage porosity arises when metal contracts unevenly as it cools, while gas porosity occurs when gas bubbles are captured within the metal. Professional casting impregnation fills these cavities effectively, preventing issues like cracking, leaks, or failure under pressure. This makes it an essential step in ensuring consistent performance and quality across manufacturing applications.

Impacts on Performance and Reliability

Even a small degree of porosity can lead to significant performance losses in metal parts. Components exposed to high stress or pressure, such as in automotive and aerospace applications, are particularly vulnerable. When left untreated, porosity may lead to leaks, premature wear, or even catastrophic mechanical failure. Casting impregnation addresses these vulnerabilities by sealing internal voids and strengthening the material matrix. Manufacturers who use casting impregnation see marked improvements in durability and reliability, making the process an indispensable part of modern production quality assurance.

Detection and Evaluation Considerations

Before undergoing casting impregnation, components are often evaluated using precision testing methods such as X-ray imaging, ultrasonic scans, and computed tomography (CT) mapping. These non-destructive techniques identify porosity levels and distribution without harming the component. This diagnostic stage ensures that casting impregnation is applied precisely where it's needed most, optimizing the process for superior results. Advanced testing also allows professionals to tailor resin types and curing methods to each application, guaranteeing complete pore sealing and consistent product quality.

Failure of Traditional Methods Against Modern Standards

In the past, manufacturers used surface welding, patching, or re-casting to address porosity, but these methods were inconsistent and labor-intensive. Such approaches often introduced new defects or altered material properties. In contrast, casting impregnation offers a scientifically engineered, repeatable solution. By utilizing vacuum and pressure systems, this process forces resin deep into every pore, achieving results that traditional methods simply cannot match. As industries demand tighter tolerances and higher performance, casting impregnation continues to outshine older techniques.

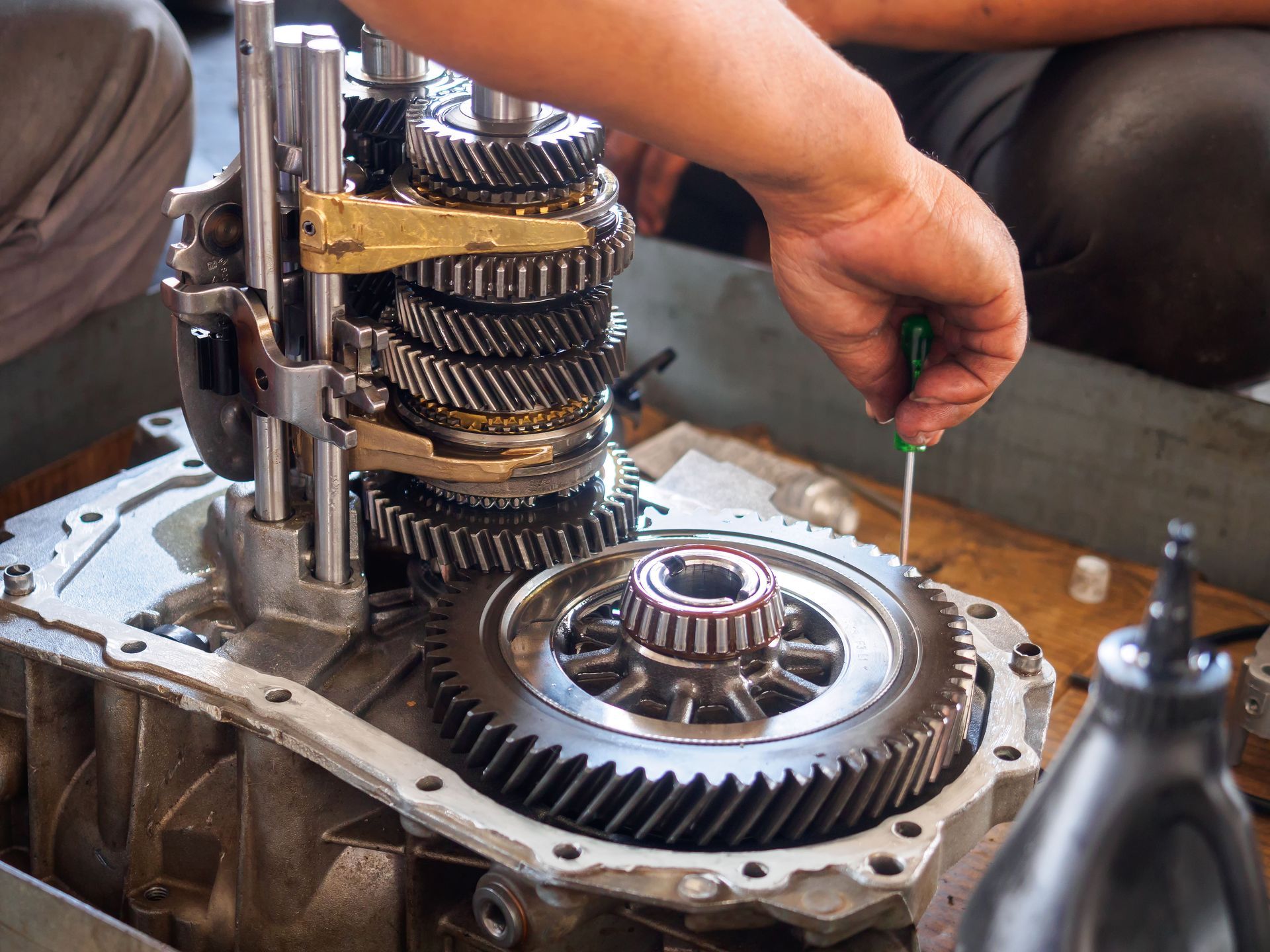

Key Steps in the Casting Impregnation Process

Professional casting impregnation follows a precise series of steps to ensure complete pore sealing. The process begins with cleaning and drying the part to eliminate contaminants. Then, the component is placed in a vacuum chamber where air is removed from the pores. A liquid resin is introduced under pressure, thoroughly filling the cavities. Once the resin has penetrated, it is cured through heat or catalyzation, solidifying inside the pores. This results in a stronger, more durable component capable of withstanding rigorous conditions.

Modern Advances Driving Efficiency

Technological innovations have greatly improved the efficiency and consistency of casting impregnation. According to Foundry Management & Technology, early vacuum and pressure impregnation systems developed in the 1960s were designed to push thick phenolic and polyester resins into metal pores, far less refined than today's high-performance sealants. Modern systems utilize thinner, more effective resins and automated controls for precision. These advancements allow casting impregnation to deliver faster cycle times, higher throughput, and superior results for a variety of complex components across multiple industries.

Advantages in Manufacturing

Casting impregnation offers numerous benefits beyond simple defect correction. It enhances the structural integrity of parts, prevents leakage, and improves surface finishes. Components treated with impregnation show greater resistance to vibration, corrosion, and high temperatures. The process also reduces material waste by salvaging components that might otherwise be scrapped due to porosity. By extending the lifespan and reliability of metal parts, casting impregnation contributes to better product performance and significant cost savings over time.

Environmental Sustainability

Today's professional casting impregnation providers embrace sustainability by using eco-friendly resins and energy-efficient processes. By salvaging defective components instead of discarding them, manufacturers reduce waste and minimize their carbon footprint. Modern resins are often low in volatile organic compounds (VOCs), aligning with environmental standards and green manufacturing goals. This commitment to sustainability enhances not only operational efficiency but also the environmental responsibility of industrial operations, showcasing casting impregnation as both an economic and ecological advantage.

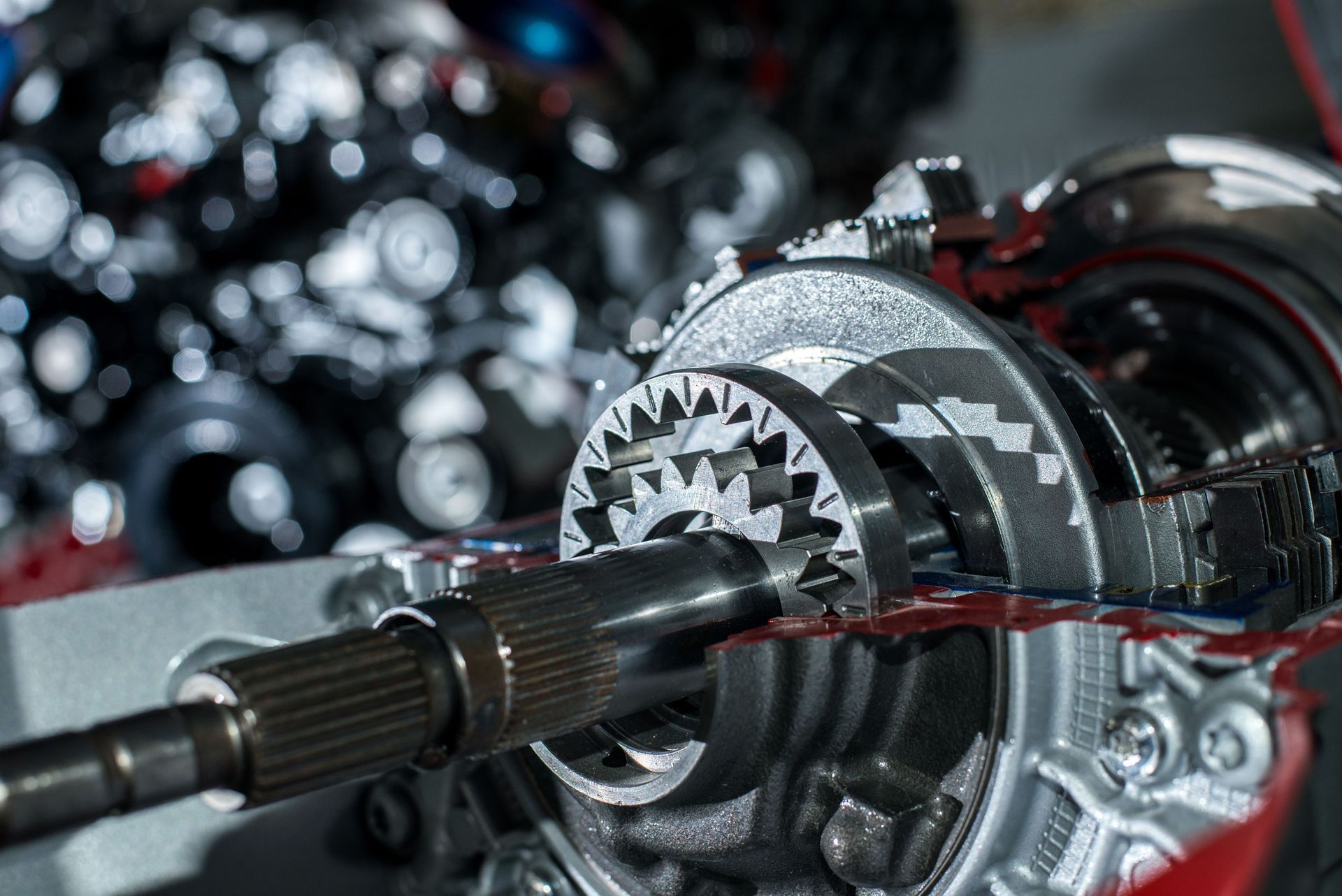

Industries That Depend on Casting Impregnation

The versatility of casting impregnation makes it invaluable across numerous industries. In automotive manufacturing, it ensures the integrity of components like engine blocks and transmission cases. Aerospace applications rely on impregnation for fuel system parts that must endure extreme pressure variations. In the energy sector, wind turbine housings and pipeline fittings benefit from the process's sealing capabilities. Even electronics and marine manufacturers use casting impregnation to protect against moisture and corrosion. This wide-ranging applicability underscores its universal importance in precision manufacturing.

Ensuring Quality Control

Maintaining rigorous quality standards is central to every successful casting impregnation process. Professionals monitor resin viscosity, curing conditions, and pressure levels to guarantee complete pore sealing. Advanced diagnostic tools verify the thoroughness of impregnation, ensuring that every treated part meets strict performance specifications. Quality assurance teams perform post-treatment inspections and non-destructive testing to confirm integrity. These measures ensure that every casting impregnation job meets industry requirements for reliability and safety, solidifying its reputation as a trusted industrial solution.

Overcoming Challenges

While casting impregnation is highly effective, challenges such as material compatibility and process control still exist. Some metals require special surface preparation to ensure proper resin adhesion, and complex geometries can complicate full resin penetration. Professional providers address these issues through precise engineering, process automation, and continuous operator training. By implementing data-driven controls and leveraging experience, they overcome these challenges and maintain high consistency in every application. Their expertise ensures dependable results even for the most intricate and high-performance components.

How Casting Impregnation Reduces Manufacturing Costs

Though the process requires specialized equipment, casting impregnation delivers exceptional return on investment. By saving components that might otherwise be discarded, it dramatically reduces waste and rework costs. Additionally, impregnated parts experience fewer failures, minimizing warranty claims and maintenance expenses. Integrating casting impregnation into production lines helps manufacturers maintain efficiency without sacrificing quality. For industries operating under tight budgets and strict standards, this process represents both a technical and economic win, reinforcing its value as a long-term solution.

Training and Expertise

Professional casting impregnation requires technical expertise, precision, and attention to detail. Skilled operators must understand resin chemistry, pressure dynamics, and quality assurance procedures to achieve consistent outcomes. Many companies invest in ongoing employee training to keep up with the latest technological advancements and process innovations. This dedication to workforce education ensures optimal performance and reliability. When customers choose an experienced casting impregnation provider, they gain the benefit of decades of specialized knowledge and craftsmanship that guarantee superior component quality.

Future Innovations and Trends

The future of casting impregnation lies in continued innovation and integration with smart manufacturing systems. Automation, real-time monitoring, and predictive analytics will enhance precision and reduce processing times. Environmentally sustainable resins and nanotechnology-based sealants promise even greater strength and performance. As industries demand higher efficiency and reduced waste, casting impregnation will evolve to meet these expectations. Its adaptability and proven results ensure that it remains at the forefront of advanced manufacturing techniques worldwide.

Casting impregnation remains one of the most effective methods for addressing porosity in metal components. By combining scientific precision, sustainability, and professional expertise, the process restores structural integrity and extends component life. Manufacturers benefit from improved product performance, cost savings, and environmental responsibility. With ongoing innovation and a growing focus on quality, casting impregnation continues to shape the future of global manufacturing, ensuring reliability and excellence across every industry it serves. Contact A B Seals Inc today for more information.

Share On: