The Origins of Metal Casting Impregnation

Metal casting impregnation has played a pivotal role in manufacturing for decades, serving as a critical solution to one of the most persistent challenges in foundry work: porosity in cast metals. Porosity occurs when microscopic voids or air pockets form within a casting, creating weak points that can compromise structural integrity, functionality, and lifespan. Metal casting impregnation addresses this issue by sealing these voids, improving performance and reliability across countless industrial applications. From automotive components to aerospace parts, this process ensures that castings meet the rigorous standards modern engineering demands.

The significance of metal casting impregnation extends beyond simply improving quality. It represents the intersection of materials science, chemistry, and mechanical engineering, offering a practical way to enhance durability while reducing waste. By understanding its origins and evolution, manufacturers and engineers can appreciate not only its technical merits but also its transformative effect on production processes.

What Is Metal Casting Impregnation and Why Is It Important?

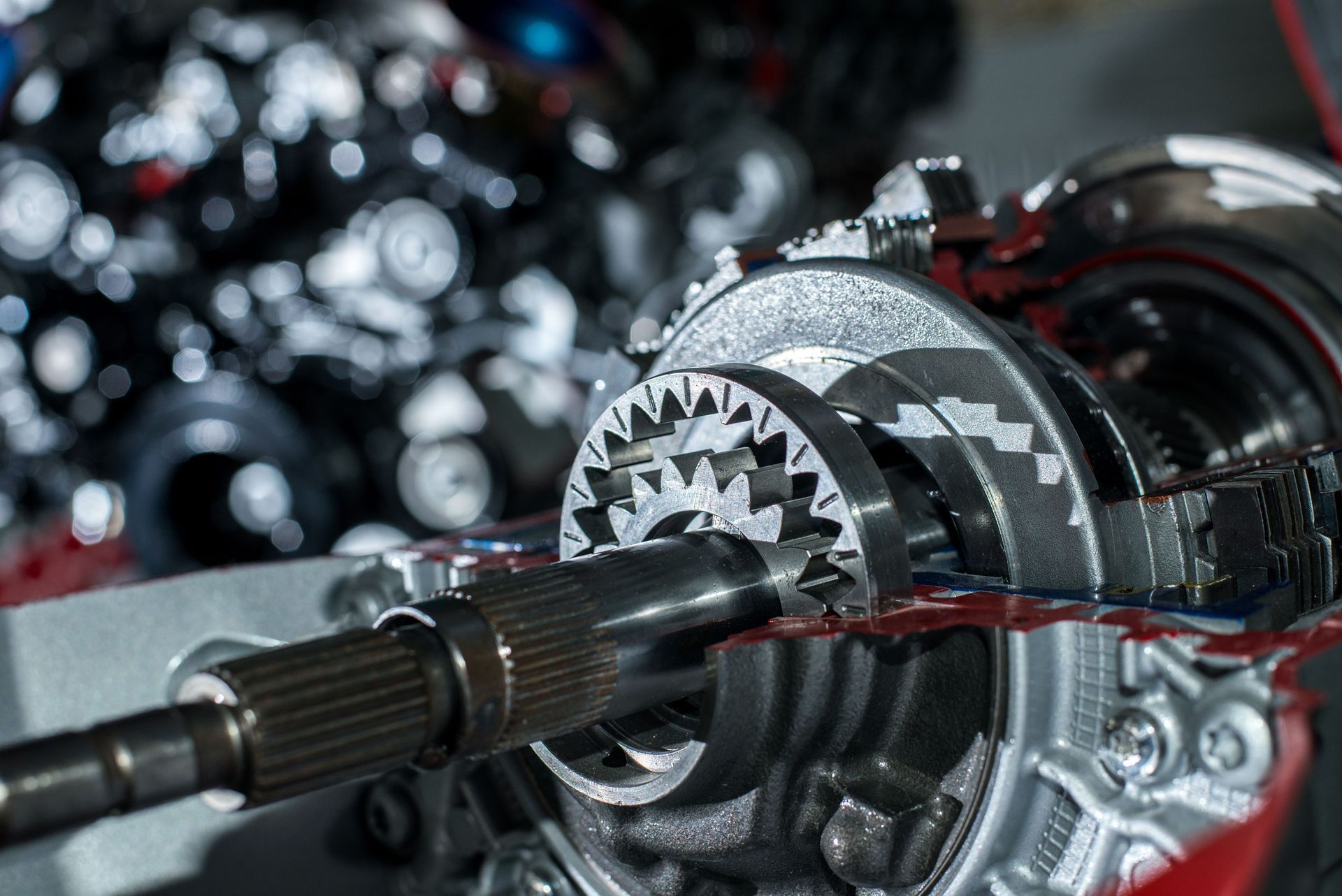

At its core, metal casting impregnation is a process that seals microscopic pores in cast metal components using specialized resins or sealants. These resins penetrate the porosity, filling gaps that could otherwise compromise the component’s strength or allow leaks. The procedure often involves a combination of vacuum and pressure to force the resin deep into the metal, ensuring complete coverage.

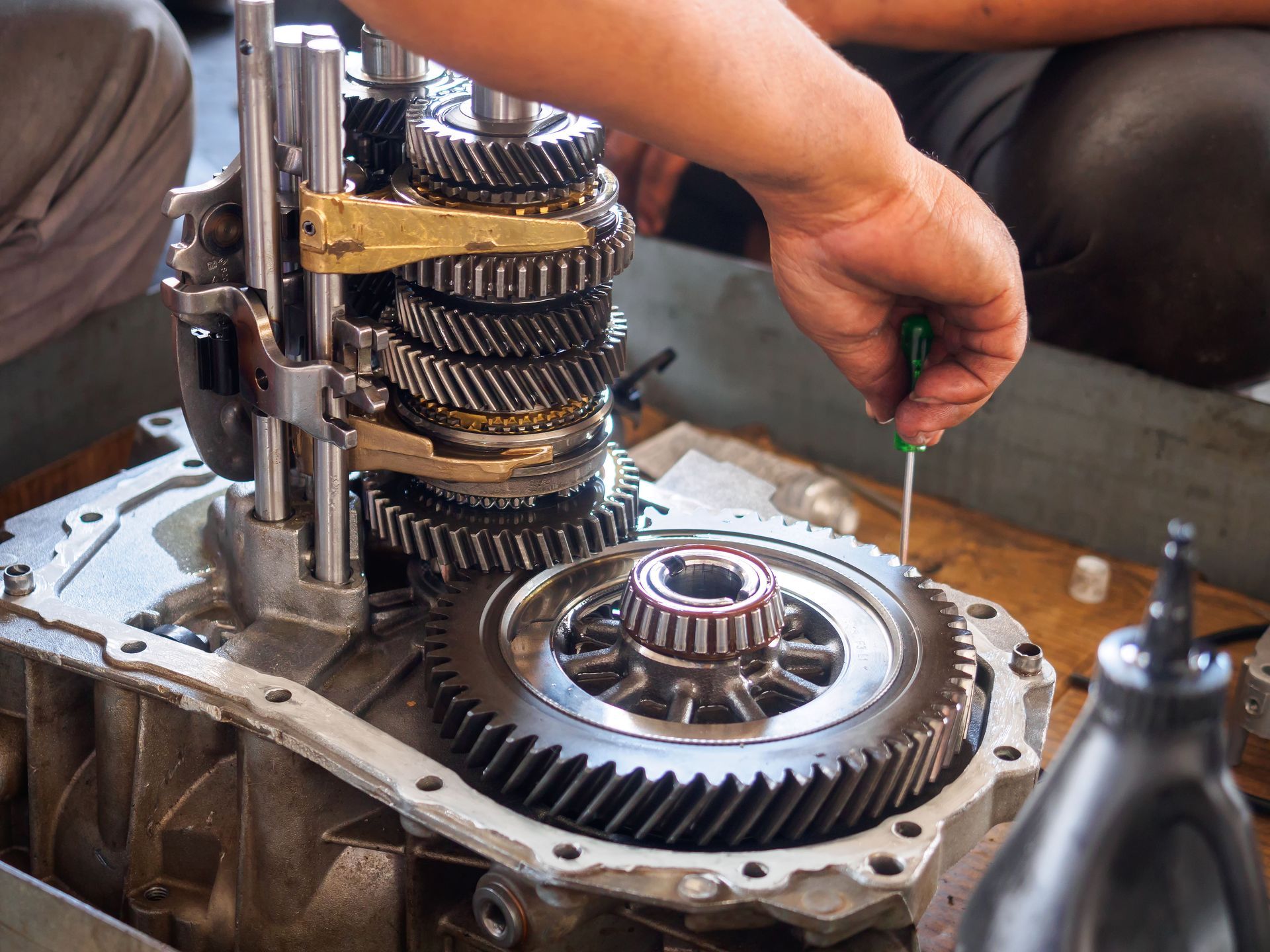

The importance of metal casting impregnation is multifaceted. Structurally, it enhances the durability and reliability of castings, which is particularly critical in industries where failure can be catastrophic, such as aerospace, automotive, and heavy machinery. Functionally, it ensures that components can withstand exposure to fluids or gases without leakage, making it indispensable in hydraulic systems, engine blocks, and pump housings. Economically, impregnation allows foundries to produce high-quality castings from less-than-perfect molds, reducing scrap rates and material waste while maintaining rigorous performance standards.

How Did Metal Casting Impregnation Originate?

The origins of metal casting impregnation trace back to the mid-20th century, when industrial foundries sought more effective ways to improve casting integrity. According to Foundry Management & Technology, vacuum and pressure impregnation plants were first designed in the 1960s to force phenolic and polyester resins into casting porosity. These early resins were considerably thicker than modern-day impregnation sealants, which limited their penetration ability but represented a groundbreaking step in sealing technology. At the time, this innovation allowed foundries to salvage castings that might otherwise have been rejected, reducing waste and improving overall efficiency. It also laid the groundwork for a more scientific approach to controlling and enhancing the performance of cast metal components.

Initially, the process focused on filling voids in iron and steel castings, which were prone to internal porosity due to the nature of molten metal solidification. Early systems relied heavily on manual intervention and rudimentary vacuum equipment. Over time, innovations such as improved resin formulations, automated vacuum and pressure cycles, and precision monitoring transformed metal casting impregnation into a highly efficient, reliable process. These advancements enabled foundries to meet stricter quality standards and expand the applications of impregnated castings across new industries. As a result, what began as a specialized solution for structural integrity gradually became a standard practice in producing high-performance metal components, shaping the trajectory of modern manufacturing.

What Materials and Techniques Are Involved in Metal Casting Impregnation?

Modern metal casting impregnation relies on a combination of specialized materials and precise techniques to ensure consistent results. The primary materials are resin-based sealants, including epoxy, acrylic, and polyurethane formulations, each tailored to specific casting types and operational requirements. These resins are designed to penetrate porosity effectively, adhere to metal surfaces, and cure to a durable, leak-resistant finish.

The techniques used have also evolved significantly. Vacuum/pressure impregnation remains the industry standard, where a casting is first evacuated to remove trapped air and then subjected to pressure to drive the resin into microscopic pores. In addition to traditional resins, some foundries now use low-viscosity sealants that offer deeper penetration and faster curing times, improving efficiency and component performance. Other technological advancements include temperature-controlled chambers, automated monitoring systems, and environmentally friendly resin formulations that reduce waste and improve safety for workers.

Overall, the combination of high-quality resins and sophisticated vacuum/pressure techniques allows modern metal casting impregnation to deliver precise, consistent results that early innovators could only imagine.

What Are the Benefits and Challenges of Metal Casting Impregnation?

Metal casting impregnation provides significant benefits that make it a critical process in modern manufacturing. First and foremost, it improves the structural integrity of cast components, reducing the risk of failure due to internal voids. This benefit extends the lifespan of parts and contributes to higher overall product reliability. Additionally, it enables foundries to salvage castings that might otherwise be rejected due to porosity, reducing material waste and increasing overall efficiency. Impregnation also enhances fluid containment in components that carry oils, coolants, or gases, ensuring leak-free operation in critical machinery.

Despite its advantages, metal casting impregnation does come with challenges. The process requires precise control of temperature, pressure, and vacuum conditions, which can be costly and technologically demanding. Selecting the appropriate resin for a specific casting material and operational environment is essential, as mismatches can result in incomplete penetration or premature failure. Moreover, ensuring consistent quality across high-volume production runs demands sophisticated monitoring and testing equipment, adding to operational complexity. Finally, while modern sealants are far more effective than early phenolic and polyester resins, some highly intricate or extremely porous castings can still present difficulties that require custom solutions.

How Is Metal Casting Impregnation Adapting to Future Trends?

As manufacturing continues to evolve, so too does metal casting impregnation. Emerging trends in automation, additive manufacturing, and sustainable materials are reshaping how foundries approach impregnation processes. Automated vacuum/pressure systems now feature integrated sensors and data analytics, allowing real-time monitoring of resin penetration and curing cycles. This automation reduces human error, improves efficiency, and ensures consistently high-quality results across large production runs.

Additive manufacturing, or 3D printing of metal components, introduces new challenges and opportunities for impregnation. Printed metal parts often have complex geometries and variable porosity patterns, requiring advanced sealant formulations and adaptive vacuum/pressure cycles to achieve complete penetration. At the same time, advances in low-viscosity, environmentally friendly resins allow foundries to meet stricter regulatory standards while reducing waste and chemical exposure for workers.

Looking ahead, the integration of predictive analytics and digital twin technology may further enhance metal casting impregnation. Foundries could simulate porosity patterns and resin flow in virtual models before actual production, optimizing processes and minimizing defects. These developments suggest that metal casting impregnation will continue to adapt to new manufacturing challenges while remaining a cornerstone of quality assurance for cast metal components.

Metal casting impregnation has a rich history and remains a vital process in modern manufacturing. From its origins in the 1960s with thick phenolic and polyester resins to the sophisticated vacuum/pressure systems of today, it has consistently improved the reliability, functionality, and economic efficiency of metal castings. By sealing microscopic porosity, metal casting impregnation ensures that critical components perform as intended in demanding industrial environments.

As materials, techniques, and automation continue to advance,

metal casting impregnation will evolve to meet the challenges of modern manufacturing. Its ability to enhance structural integrity, reduce waste, and adapt to new trends highlights its ongoing relevance and transformative impact on industries worldwide. If you need expert metal casting, reach out to the experienced professionals at A B Seals Inc today!

Share On: